Page 241 - Globus Group Catalogue

P. 241

GUIDE TO HAND PROTECTION STANDARDS

EUROPEAN DIRECTIVE 93/42/EEC

Covering medical examination and surgical gloves

EN 455-1:2000 A random sample of gloves is tested for freedom of holes by undergoing a water leak penetration test.

Freedom from holes The gloves are filled with 1l of water and must remain completely leak proof over a defined period of

time. A failed test results in a higher AQL value, which for medical gloves sold in Europe must be 1,5 or

lower. AQL (accepted quality level) is a quality sampling procedure ISO 2859-1 used by manufacturers

for measuring the % likelihood of pinhole defects in a batch of single use gloves. An AQL of 1,5 brings a

statistical probability that less than 1,5% of the gloves in the batch will have defects.

EN 455-2:2015 Size and tensile strength requirements for single use medical gloves.

Physical properties No less than 240mm in median length and 95mm (±10mm) median width to provide adequate

protection along full length of the hand (exception for long cuff gloves).

Strength is measured by elongation until breaking point, indicated as Force At Break (FAB) in newton

(N). FAB is measured on standard sample and on a rapid aged sample that is kept at 70°C for 7 days to

simulate glove deterioration during prolonged shelf life. FAB requirements differ per glove material and

if the glove is for examination or surgical purpose. Indication of median minimum FAB values:

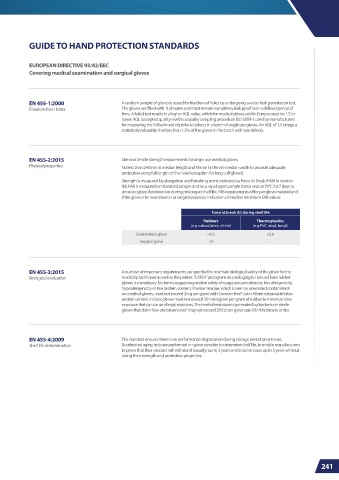

Force at break (N) during shelf life

Rubbers Thermoplastics

(e.g natural latex, nitrile) (e.g PVC, vinyl, butyl)

Examination glove >6.0 ≥3.6

Surgical glove >9 -

EN 455-3:2015 A number of important requirements are specified to maintain biological safety of the glove for the

Biological evaluation medical practitioner as well as the patient. “LATEX” pictogram on packaging for natural latex rubber

gloves is mandatory. No terms suggesting relative safety of usage are permitted i.e. low allergenicity,

hypoallergenicity or low protein content. Powder residue, which is seen as unwanted contaminant

on medical gloves, must not exceed 2mg per glove with “powder-free” claim. Water extractable latex

protein content in latex gloves must not exceed 50 microgram per gram of rubber to minimize latex

exposure that can cause allergic reactions. The level of endotoxins generated by bacteria on sterile

gloves that claim “low endotoxin level” may not exceed 20 EU per glove pair (EU=Endotoxin Units).

EN 455-4:2009 The standard ensures there is no performance degradation during storage period prior to use.

Shelf life determination Accelerated aging tests are performed on glove samples to determine shelf life, to enable manufacturers

to prove that their product will withstand (usually) up to 3 years and in some cases up to 5 years without

losing their strength and protection properties.

241