Page 239 - Globus Group Catalogue

P. 239

GUIDE TO HAND PROTECTION STANDARDS

EN 374-4:2013 Degradation is the deleterious change in one or more properties of a protective glove material

Resistance to chemical degradation due to contact with a chemical. Indications of degradation can be delaminating, discoloration,

hardening, softening, dimensional change, loss of tensile strength, etc. It is determined

by measuring the percentage change in puncture resistance of the glove material after a

continuous contact for 1 hour of the external surface with the challenge test chemical. The

results of the degradation test must appear in the information leaflet for all three glove types.

EN ISO 374-5:2016 Micro-organisms are defined by the standard as bacteria, fungi or viruses. To claim resistance

Protection against micro-organisms to bacteria and fungi the glove must pass the penetration resistance test according to standard

EN 374-2: 2014. If the glove passes ISO 16604: 2004 (method B) test it can claim resistance to

EN ISO 374-5 EN ISO 374-5 viruses as well, and the term “VIRUS” will be added below the biohazard pictogram.

VIRUS

EN ISO 374-1:2016 The standard defines requirement the capability of gloves to protect the user against

penetration, permeation and degradation by chemicals and microorganisms. It classifies three

types of gloves by level of protection (A, B, and C) using test method EN16523-1:2015.

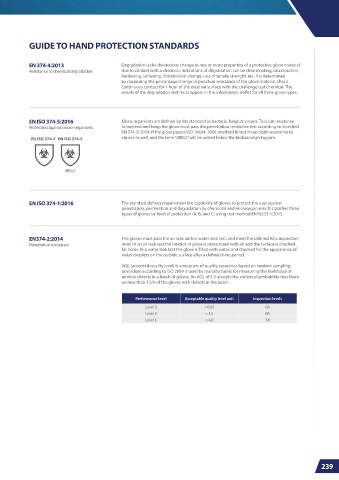

EN374-2:2014 The gloves must pass the air leak and/or water leak test, and meet the defined AQL inspection

Penetration resistance level. In an air leak test the interior of glove is pressurized with air and the surface is checked

for holes. In a water leak test the glove is filled with water, and checked for the appearance of

water droplets on the outside surface after a defined time period.

AQL (accepted quality level) is a measure of quality assurance based on random sampling

procedure according to ISO 2859-1 used by manufacturers for measuring the likelihood of

pinhole defects in a batch of gloves. An AQL of 1,5 accepts the statistical probability that there

are less than 1,5% of the gloves with defects in the batch.

Performance level Acceptable quality level unit Inspection levels

Level 3 < 0,65 G1

Level 2 < 1,5 G1

Level 1 < 4,0 S4

239